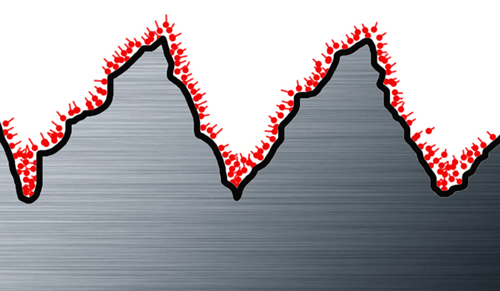

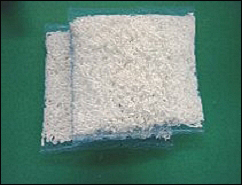

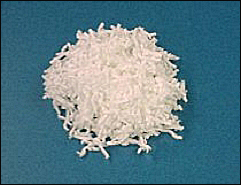

This film has a very strong, following feature.  The protective surface film has strength twice and more than the oil slick of the lubricant. It keeps adhering to the metal even if it runs short of oil. It defend the machine and the engine from the lubricant shortage on the unexpected circumstances. It slips well because the coefficient of friction is below the half of oil, the load is decreased, and the noise is decreased. The protective surface film keeps it without burning, even if it faces the high temperature. (The limiting temperature of the lubricant is up to about 282℃) Dia-lubex makes the protective surface film on the metal, even if it is in the seawater and/or fresh water, at the result ,the rust development of the metal should be prevented ●SUPER   Use part: When the auxiliary machinery and equipment is overhauled, put it's parts into SUPER oil about one day, and after assemble parts. Add 2-5% SUPER oil to the lubricant of each auxiliary machinery and equipment. Add 2-5% SUPER oil to the lubricant of intermittent use machinery which has the fear of disappear the oil film such as emergency generator, emergency fire pump,and standby equipment, etc. Effect: The following effect remarkably becomes visible. A decrease in wear-out of machinery A noise decrease of machinery Driving power decrease of machinery Cooling temperature decrease of machinery Once protective surface film is put to the Metal surface, it will not take off even if oil disappears, At the result, when engine start oil less condition, It is protected from wear-out of engine parts. ●HIGH-POWER EP SPRAY  Use part: Especially, part that hangs seawater, and rusts. Lubrication part of grease such as pins of cylinder for hatch cover opening and shutting. Water tight door handle, Bolt and nut of manhole cover, hinges, etc. Lubrication part of grease of desk machinery and wire pulley on deck. Lubrication part of grease of pump bearings. Especially, hard contact area by misalignment or noisy parts. Effect: Because the protective surface film defends metal from water and seawater, rust prevention is effective. Because High-power EP spray is half of the lubricant the coefficient of friction, It slips well and driving power decrease of machinery. It also decreases, the noise, and generation of heat. These effects continue for a long time. ●HIGH-POWER EP GREASE   MSDS for HIGH-POWER EP MSDS for HIGH-POWER EXCELLENT User part: Lubrication part of the deck machinery that hangs seawater. Upper part of deck crane where grease injection is troublesome and hinge pin of hatch cover etc. Especially, Part where contact pressure is strong. Effect: High-power EP grease is excelling in the following item. Wear-proof Corrosion control of metal. Withstand load Water-proof Rust prevention ●GEAR ROY  Use part: Gearwheel of Purifier with the brush. Wire and chain, etc. with the brush. Rail of the hatch cover with the brush. Gearwheel of the deck crane rotation part with the brush. Effect: Wear-out prevention Generation of heat prevention Flaking off prevention Burning prevention It is also possible to be used for the part where water and the medicine splash. It lower the coefficient of friction, improve the efficiency of transmission, and decrease the loss of power. ●OIL CATCHER 'ABURATO-RU'   Use part: Put in the M.E. piston cooling fresh water tank, and the oil that flows from the stuffing box is absorbed. Put in scupper on the deck, and the oil that flows from the deck is absorbed. Put in container that have fine mesh hole, and pouring the liquid that oil and water mixed , at the results, only oil is absorbed in the [Aburato-ru]. Effect: The polypropylene is cut in detail, and it is an absorption area and absorption capacity. has been enlarged. As the static electricity prevention has been processed, volatility oil and the solvent is possible to use it at ease. Moisture is not absorbed, and only oil is absorbed. Moreover, the absorbed amount of oil is large, and it is excellent also in preservation for a long term. As for [aburato-ru] that absorbs oil, the incineration processing can be done. |